Will the charger ports of electronic intelligent products be unified

Will the charger ports of electronic intelligent products be unified,

electronic intelligent products,

| No number |

Certification / coverage |

Certification specification |

Suitable for the product |

Note |

|

1 |

Battery transport | UN38.3. | Battery core, battery module, battery pack, battery system | Change content: The battery pack / battery system above 6200Wh can be tested using the battery module. |

|

2 |

CB certification | IEC 62660-1. | Battery unit | |

| IEC 62660-2. | Battery unit | |||

| IEC 62660-3. | Battery unit | |||

|

3 |

GB certification | GB 38031. | Battery core, battery pack, battery system | |

| GB/T 31484. | Battery unit, battery module, battery system | |||

| GB/T 31486. | Battery core, battery module | |||

|

4 |

ECE certification | ECE-R-100. | Battery pack, battery system | Countries and regions that recognize the European and ECE decrees |

|

5 |

India | AIS 048. | Battery pack, Battery system (L, M, N vehicles) | Waste paper time: No. 04.01,2023 |

| AIS 156. | Battery pack, Battery system (L vehicles) | Forced time: 04.01.2023 | ||

| AIS 038. | Battery pack, Battery system (M, N vehicles) | |||

|

6 |

North America | UL 2580. | Battery core, battery pack, battery system | |

| SAE J2929. | Battery system | |||

| SAE J2426. | Battery unit, battery module, battery system | |||

|

7 |

Vietnam | QCVN 91:2019/BGTVT. | Electric motorcycles / mopeds-Lithium batteries | Exam + Factory Review + VR registration |

| QCVN 76:2019/BGTVT. | Electric bike-lithium batteries | Exam + Factory Review + VR registration | ||

| QCVN47:2012/BGTVT. | Motorcycle and Morpet- – – -lead acid batteries | |||

|

8 |

Other certification | GB/T 31467.2. | Battery pack, battery system | |

| GB/T 31467.1. | Battery pack, battery system | |||

| GB/T 36672. | Battery for electric motorcycles | The CQC/CGC certification can be applied for | ||

| GB/T 36972. | Electric bike battery | The CQC/CGC certification can be applied for |

Power battery certification profile

“ECE-R-100.

ECE-R-100: Battery Electric Vehicle Safety (Battery Electric Vehicle Safety) is a regulation enacted by the European Economic Commission (Economic Commission of Europe,ECE).Currently, ECE includes 37 European countries, apart from EU Member States, countries including Eastern Europe and South Europe. In Security Testing, the ECE is the only official standard in Europe..

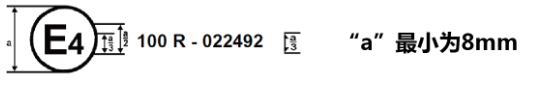

“Use ID: A certified electric vehicle battery can use the following identification:

E4: represents the Netherlands (code varies from country and regionFor example, the E5 represents Sweden. ).

100R: Decree No

022492: Approval Number (Certificate Number)

“Test content: The evaluation object is a battery pack, and some of the tests can be replaced by modules.

|

No number |

Evaluation items |

|

1 |

Vibration test |

|

2 |

Thermal impact cycle test |

|

3 |

Mechanical impact |

|

4 |

Mechanical integrity (compaction) |

|

5 |

Fire resistance test |

|

6 |

External short-circuit protection |

|

7 |

Overcharge protection |

|

8 |

Overdischarge protection |

|

9 |

Overtemperature protection |

Provisions on the Administration of Circulation License of Chinese New energy vehicle production enterprises and products

()> on Circulation License Management of New Energy Vehicle Production Enterprises and Products was passed at the 26th meeting of the Ministry of Industry and Information Technology on October 20,2016 and came into effect on July 1,2017.

“New Energy Vehicle Battery Test Items and Standards:

|

No number |

Certification specification |

Standard name |

Note |

|

1 |

GB 38031. | Power Battery safety requirements for electric vehiclesIn, the | Replace of GB/T 31485 and GB/T 31467.3 |

|

2 |

GB/T 31484-2015. | Power battery cycle life requirements and test methods for electric vehiclesIn, the | 6.5 The cycle life is tested together with the vehicle reliability standards |

|

3 |

GB/T 31486-2015. | Power battery for electric vehicles. Electrical performance requirements and test methodsIn, the | |

| Note: The electric passenger vehicles shall meet the requirements of the Safety Technical Conditions for Electric Passenger Vehicles. | |||

India power battery test requirements and brief introduction

. . . . 1997In 1989, the Government of India promulgated the Central Automobile Act (Central Motor Vehicles Rules,CMVR) which required all road cars, construction machinery vehicles, agricultural and forestry machinery vehicles, etc. applicable to CMVR to apply to the certification bodies recognized by the Ministry of Transport of India. The enactment meant the beginning of Indian automobile certification. Thereafter, the Indian Government required the main safety components for vehicles to also be used on 15 September and we established the Automotive Industry Standards Committee (Automotive Industry Standard Committee,AISC) where ARA was responsible for drafting and issuing the draft standards.

. Power battery as one of the safety components of the vehicle regarding its safety test AIS 048, released AIS 156 and AIS 038-Rev.2 rules and standards of which the earliest implemented AIS 048 standards will be abolished on 1 April 2023. Manufacturers can apply for certification before abolishing this standard AIS 038-Rev.2 and AIS 156 will replace AIS 048, mandatory from 1 April 2023.. Therefore, the manufacturer may apply for power battery certification to the corresponding standards.

“Use the mark:

No Mark.Currently power batteries in India can be certified to each other with standard test scores, but there are no relevant certificates and certification marks.

“Test content:

|

|

AIS 048. |

AIS 038-Rev.2. |

AIS 156. |

| Implementation date | Repeidated 01 April 2023 | 01 April 2023 and currently available to manufacturers | |

| Reference standards | — | UNECE R100 Rev.3.Technical requirements and test methods are the same as the UN GTR 20 Phase1 | UNECE R136. |

| Scope of application | L, M, N vehicles | M, N vehicles | L vehicles |

Vietnam VR Compulsory Certification Introduction

Introduction to Vietnam Automobile Certification System

Beginning in 2005, the Vietnamese government enacted a series of regulations establishing certification requirements for cars and their parts.The Automatic Vehicle Registration Bureau under the Ministry of Transport of Vietnam, as the market circulation licensing management department of the products, implements the Vietnam Register system (VR certification).

The certification type is the form of vehicle, mainly as follows:

No.58 / 2007 / QS-BGTV: On November 21,2007, the Minister of Transport stipulated that motorcycles and mopeds manufactured and assembled in Vietnam must receive official approval.

On July 21, NO.34/2005/QS-BGTV:2005, the Minister of Transport issued type approval specifications for cars manufactured and assembled in Vietnam.

On 21 November NO.57/2007/QS-BGTVT:2007, the Minister of Transport issued test specifications for imported motorcycles and engines.

No..35 / 2005 / QS-BGTVT:2005 On July 21, the Minister of Transport promulgated the test specification for imported automobile vehicles.

VR Product Certification in Vietnam:

The Vietnam Automotive Registration Authority began in April 2018 to require aftermarket service auto parts obligations to perform Vietnam VR certification.Current mandatory certification products include: helmet, safety glass, wheels, rearview mirrors, tires, headlights, fuel tanks, battery, interior materials, pressure vessels, power batteries, etc.

“Power battery test project

|

Test items |

Battery unit |

The module |

Battery pack |

|

|

Electrical performance |

Room temperature, high temperature, and low temperature capacitance |

√ |

√ |

√ |

|

Room temperature, high temperature, low temperature cycle |

√ |

√ |

√ |

|

|

AC, DC internal resistance |

√ |

√ |

√ |

|

|

Storage at room temperature and high temperature |

√ |

√ |

√ |

|

|

Safety |

Heat exposure |

√ |

√ |

N/A. |

|

Overcharge (protection) |

√ |

√ |

√ |

|

|

Over-discharge (protection) |

√ |

√ |

√ |

|

|

Short-circuit (protection) |

√ |

√ |

√ |

|

|

Overtemperature protection |

N/A. |

N/A. |

√ |

|

|

Overload protection |

N/A. |

N/A. |

√ |

|

|

Wear the nail |

√ |

√ |

N/A. |

|

|

Press ressing |

√ |

√ |

√ |

|

|

Rotate |

√ |

√ |

√ |

|

|

Subtest test |

√ |

√ |

√ |

|

|

Force the internal paragraph |

√ |

√ |

N/A. |

|

|

Thermal diffusion |

√ |

√ |

√ |

|

|

Environment |

Low air pressure |

√ |

√ |

√ |

|

Temperature impact |

√ |

√ |

√ |

|

|

Temperature cycle |

√ |

√ |

√ |

|

|

Salt mist test |

√ |

√ |

√ |

|

|

Temperature and humidity cycle |

√ |

√ |

√ |

|

| Note: The N/A. is not applicable② does not include all evaluation items, if the test is not included in the above scope. | ||||

Why is it the MCM?

“Large measuring range, high-precision equipment:

The 1) has battery unit charge and discharge equipment with 0.02% accuracy and maximum current of 1000A, 100V/400A module test equipment, and battery pack equipment of 1500V/600A.

The 2) is equipped with 12m³ constant humidity, 8m³ salt fog and high and low temperature compartments.

3)Equipped with piercing equipment displacement up to 0.01 mm and compaction equipment weighing 200 tons, drop equipment and 12000A short circuit safety test equipment with adjustable resistance.

4)Have the ability to digest a number of certification at the same time, to save customers on samples, certification time, test costs, etc.

5)Work with examination and certification agencies around the world to create multiple solutions for you.

6)We will accept your various certification and reliability test requests.

“Professional and technical team:

We can tailor a comprehensive certification solution for you according to your system and help you get quickly to the target market.

We will help you develop and test your products, and provide accurate data.

Post time:

Jun-28-2021

The proposal No.5080 at the fourth session of the 13th National Committee of the CPPCC proposes to unify the charger ports of electronic intelligent products in order to reduce e-waste and promote carbon neutralization.

The MIIT has made a reply to this proposal: With the rapid iteration of charging/data ports and charging technology, the current intelligent terminal market has formed a pattern which is dominated by USB-C interface and a variety of ports and charging technology coexist.

As the proposal says, the most of original chargers and USB cables will be put aside and cause a big waste after users change their devices. Giving great impetus to charging ports and technique fusion can reduce e-waste and improve the rate of resource utilization.

The reply of MIIC indicates to promote the unification of charging ports and technique fusion, and improve recovery rate of resource, which also means that charging ports will be approved. In the meantime, the recovery processing of electronic products will be enhanced, and the recovery rate of electronic products like abandoned charges will also be improved.