UL 1642 added a test requirement for solid state cells

UL 1642 added a test requirement for solid state cells,

UL 1642,

▍Document requirement

1. UN38.3 test report

2. 1.2m drop test report (if applicable)

3. Accreditation report of transportation

4. MSDS(if applicable)

▍Testing Standard

QCVN101:2016/BTTTT(refer to IEC 62133:2012)

▍Test item

1.Altitude simulation 2. Thermal test 3. Vibration

4. Shock 5. External short circuit 6. Impact/Crush

7. Overcharge 8. Forced discharge 9. 1.2mdrop test report

Remark: T1-T5 is tested by the same samples in order.

▍ Label Requirements

|

Label name |

Calss-9 Miscellaneous Dangerous Goods |

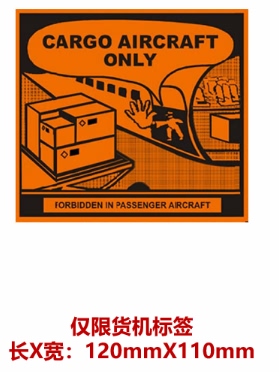

Cargo Aircraft Only |

Lithium Battery Operation Label |

|

Label picture |

|

|

▍Why MCM?

● The initiator of UN38.3 in the transportation field in China;

● Have the resources and professional teams being able to accurately interpret UN38.3 key nodes related to Chinese and foreign airlines, freight forwarders, airports, customs, regulatory authorities and so on in China;

● Have resources and capabilities that can help lithium-ion battery clients to “test once, pass smoothly all airports and airlines in China “;

● Has the first-class UN38.3 technical interpretation capabilities, and housekeeper type service structure.

Following last month’s addition of heavy impact for pouch cell, this month UL 1642 proposed to add a test requirement for solid state lithium cells.At present, most solid state batteries are based on lithium-sulfur batteries. Lithium-sulfur battery has high specific capacity (1672mAh/g) and energy density (2600Wh/kg), which is 5 times that of traditional lithium-ion battery. Therefore, solid state battery is one of the hot-spot of lithium battery. However, the significant changes in the volume of sulfur cathode during the process of delithium/lithium, the dendrite problem of lithium anode and the lack of conductivity of solid electrolyte have hindered the commercialization of sulfur cathode. So for years, researchers have been working on improving the electrolyte and interface of solid state battery.UL 1642 adds this recommendation with the goal of effectively solving the problems caused by the solid battery (and cell) characteristics and potential risks when in usage. After all, cells containing sulphide electrolytes may release the toxic gas like hydrogen sulphide under some extreme conditions. Therefore, in addition to some routine tests, we also need to measure toxic gas concentration after the tests. Specific test items include: capacity measurement, short circuit, abnormal charge, forced discharge, shock, crush, impact, vibration, heating, temperature cycle, low pressure, combustion jet, and measurement of toxic emissions.