The release of UL 2054 edition three

The release of UL 2054 edition three,

UL 2054,

▍What is TISI Certification?

TISI is short for Thai Industrial Standards Institute, affiliating to Thailand Industry Department. TISI is responsible for formulating the domestic standards as well as participating in international standards formulation and supervising the products and qualified assessment procedure to ensure the standard compliance and recognition. TISI is a governmental authorized regulatory organization for compulsory certification in Thailand. It is also responsible for formation and management of standards, lab approval, personnel training and product registration. It is noted that there is no non-governmental compulsory certification body in Thailand.

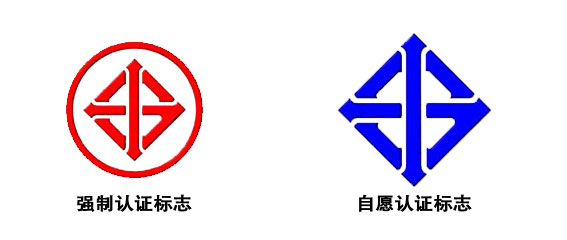

There is voluntary and compulsory certification in Thailand. TISI logos (see Figures 1 and 2) are allowed to use when products meet the standards. For products that have not yet been standardized, TISI also implements product registration as a temporary means of certification.

▍Compulsory Certification Scope

The compulsory certification covers 107 categories, 10 fields, including: electrical equipment, accessories, medical equipment, construction materials, consumer goods, vehicles, PVC pipes, LPG gas containers and agricultural products. Products beyond this scope are fall within the voluntary certification scope. Battery is compulsory certification product in TISI certification.

Applied standard: TIS 2217-2548 (2005)

Applied batteries:Secondary cells and batteries(containing alkaline or other non-acid electrolytes – safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications)

License issuance authority: Thai Industrial Standards Institute

▍Why MCM?

● MCM cooperates with factory audit organizations, laboratory and TISI directly, capable to provide best certification solution for clients.

● MCM possesses 10 years abundant experience in battery industry, capable to provide professional technical support.

● MCM provides one-stop bundle service to help clients enter into multiple markets (not only Thailand included) successfully with simple procedure.

Addition of section 6.3: General requirements for the structure of wires and terminals:

The wire should be insulated, and should meet the requirements of UL 758 while considering whether the possible temperature and voltage encountered in the battery pack is acceptable.

Wiring heads and terminals should be mechanically reinforced, and electrical contact should be provided, and there should be no tension on the connections and terminals. The lead should be safe, and kept far away from sharp edges and other parts that might harm the wire insulator.

Miscellaneous revisions are made throughout the Standard; Sections 2 – 5, 6.1.2 – 6.1.4, 6.5.1, 8.1, 8.2, 11.10, 12.13, 13.3, 14.7, 15.2, 16.6, Section 23 title, 24.1, Appendix A.

Clarification of requirements for adhesive labels; Section 29, 30.1, 30.2

addition of the requirements and methods of Mark Durability Test

Made Limited Power Source Test an optional requirement; 7.1

Clarified the external resistance in the test in 11.11.

The Short Circuit Test was stipulated to use copper wire to short circuit positive and negative anodes on section 9.11 of original standard, now was revised as using 80±20mΩ external resistors.