Requirement of the Standard

Requirement of the Standard,

TISI,

▍What is TISI Certification?

TISI is short for Thai Industrial Standards Institute, affiliating to Thailand Industry Department. TISI is responsible for formulating the domestic standards as well as participating in international standards formulation and supervising the products and qualified assessment procedure to ensure the standard compliance and recognition. TISI is a governmental authorized regulatory organization for compulsory certification in Thailand. It is also responsible for formation and management of standards, lab approval, personnel training and product registration. It is noted that there is no non-governmental compulsory certification body in Thailand.

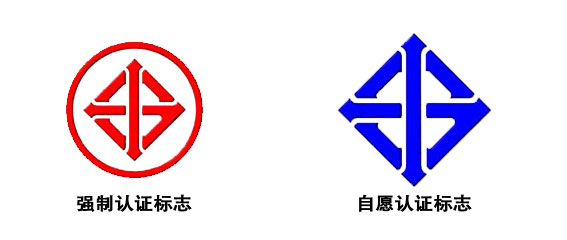

There is voluntary and compulsory certification in Thailand. TISI logos (see Figures 1 and 2) are allowed to use when products meet the standards. For products that have not yet been standardized, TISI also implements product registration as a temporary means of certification.

▍Compulsory Certification Scope

The compulsory certification covers 107 categories, 10 fields, including: electrical equipment, accessories, medical equipment, construction materials, consumer goods, vehicles, PVC pipes, LPG gas containers and agricultural products. Products beyond this scope are fall within the voluntary certification scope. Battery is compulsory certification product in TISI certification.

Applied standard: TIS 2217-2548 (2005)

Applied batteries:Secondary cells and batteries(containing alkaline or other non-acid electrolytes – safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications)

License issuance authority: Thai Industrial Standards Institute

▍Why MCM?

● MCM cooperates with factory audit organizations, laboratory and TISI directly, capable to provide best certification solution for clients.

● MCM possesses 10 years abundant experience in battery industry, capable to provide professional technical support.

● MCM provides one-stop bundle service to help clients enter into multiple markets (not only Thailand included) successfully with simple procedure.

Appearance and markThe appearance should be intact; the surface should be clean; the parts andcomponents should be complete. There should be no mechanical defects, no extras and other defects. The product identification shall include the polarity and traceable product number, where the positive pole is represented by “+” and the negative pole isrepresented by “-”.

Dimensions and weightThe dimensions and weight should be consistent with the technical specifications of thestorage battery.Airtightness

The leakage rate of the storage battery is not more than 1.0X10-7Pa.m3.s-1; after thebattery is subjected to 80,000 fatigue life cycles, the welding seam of the shell should not be damaged or leaked, and the burst pressure should not be lower than 2.5MPa.For the requirements of tightness, two tests are designed: leakage rate and shell burst pressure; the analysis should be on test requirements and test methods: these requirements mainly consider the leakage rate of the battery shell under low pressure conditions and its

ability to withstand gas pressure.

Electrical performanceAmbient temperature (0.2ItA, 0.5ItA), high temperature, low temperature capacity, charge

and discharge efficiency, internal resistance (AC, DC), charged retention capacity, pulse test.

Environmental adaptability

Vibration (sine, random), shock, thermal vacuum, steady- state acceleration.

Compared to other standards, thermal vacuum and steady-state acceleration test chambers

have a special requirement; in addition, the acceleration of the impact test reaches 1600g,

which is 10 times the acceleration of the commonly used standard.

Safety Performance

Short circuit, overcharge, overdischarge, over-temperature test.

The external resistance of the short-circuit test should be no more than 3mΩ, and the

duration is 1min; the overcharge test is carried out for 10 charge and discharge cycles

between 2.7 and 4.5V specified current; the overdischarge is carried out between -0.8 and

4.1V (or set value) for 10 charging and discharging cycles; the over-temperature test is to

charge under specified conditions of 60℃±2℃.

Life performance

Low Earth Orbit (LEO) cycle life performance, Geosynchronous Orbit (GEO) cycle life

performance.