On June 28th 2023, the standard for energy storage battery system ANSI/CAN/UL 9540:2023:Standard for Energy Storage Systems and Equipment issues the third revision. We will analyze the differences in definition, structure and testing.

Added definitions

- Add definition of AC ESS

- Add definition of DC ESS

- Add definition of Dwelling Unit

- Add definition of Energy Storage Management System (ESMS)

- Add definition of External Warning Communication System (EWCS)

- Add definition of Flywheel

- Add definition of Habitable Space

- Add definition of Remote Software Update

New Requirement on structure

- For Battery Energy Storage System (BESS), the enclosure should meet UL 9540A Unit Level testing.

- Gasket and seals can comply with UL 50E/CSA C22.2 No. 94.2 or comply with UL 157 or ASTM D412

- If BESS uses metallic enclosure, that enclosure should be noncombustible materials or comply with UL 9540A unit.

- ESS enclosure should have certain strengthen and rigidity. This can be proved by passing test of UL 50, UL 1741, IEC 62477-1, UL 2755, ISO 1496-1 or other standards alike. But for ESS less than 50kWh, the strengthen of enclosure can be evaluated through this standard.

- Walk-in ESS unit with explosion protection and venting.

- Software that can be remotely upgraded should comply with UL 1998 or UL60730-1/CSA E60730-1 (Class B software)

- ESS with lithium-ion batteries capacity of 500 kWh or greater should be provided with an external warning communication system (EWCS) so as to give an advance notification to operators of a potential safety issue.

- Installation of EWCS should reference NFPA 72. Visual alarm should be in accordance with UL 1638. Audio alarm should be in accordance with UL 464/ ULC525. The maximum sound level for audio alarms shall not exceed 100 Dba.

- ESS containing liquids, including ESS with coolant systems containing liquid coolant, shall be provided with some means of leak detection to monitor for loss of coolant. Coolant leaks that are detected shall result in a warning signal to the ESS monitoring and control system and shall initiate an alarm if provided.

- The noise level from an ESS during operation should be limited to an 8-hour time-weighted average of 85 Dba. It can be tested through 29 CFR 1910.95 or equivalent method. System that have noise levels in excess of this limit shall be provided with warning labels and instructions. (This still exceeds the limits of the EU machinery directive, which is 80 Dba)

- Electrochemical ESS with integral enclosures where there is the potential for a flammable gas concentration within the enclosure from an abnormal condition such as thermal runaway and propagation, shall be provided with deflagration or explosion protection in accordance with NFPA 68 or NFPA 69. The protection is not required if the testing in accordance with UL 9540A with a deflagration hazard analysis demonstrates that the concentration of flammable gas measured during testing remains under 25 % LFL. For ESS cabinets/enclosures, protection other than as noted can be used if it has been determined that the ESS cabinet/enclosure has been designed to effectively protect against hazards due to combustible concentrations when the ESS has been tested in accordance with the Unit Level or Installation Level test of UL 9540A.

- ESS containing hazardous solids (i.e. pyrophoric or water reactive metals) shall be designed and installed in accordance with NFPA 484.

New added testing items

Leakage tests

For ESS utilizing liquid coolant or contain hazardous fluids, a fluid of 1.5 times (if testing with liquid) the maximum operating pressure or 1.1 times the maximum operating pressure (if air pneumatic testing) should be subjected to the fluid-containing parts. There shall be no leaks from the parts.

1.Enclosure impact

Drop a steel sphere with 50.8 mm in diameter and weighting 535 g from a height of 1.29 m on the surface of a sample.

Suspend the steel sphere with a cord and swung as a pendulum, dropping through the vertical height of 1.29m to impact the side faces.

After the impacts, the DUT shall be subjected to a Dielectric Voltage Withstand Test. The DUT shall be examined for signs of rupture or damage. There shall be no damage to the enclosure that could result in a hazard such as exposure of hazardous parts or result in a dielectric breakdown.

2.Enclosure steady force

This test is conducted on electrochemical ESS that are for residential applications or for non-residential applications that are less than or equal to 50 kWh. The sample should withstand a force of 250N ± 10N with a circular test tool of 30 mm in diameter. The test should be conducted in turn to the top, bottom and sides of the enclosure. The DUT shall be subjected to a Dielectric Voltage Withstand Test. There shall be no damage or dielectric breakdown.

3.Mold stress

This test is for molded polymeric material enclosure. Place the sample in an oven maintained at a uniform temperature of at least 10℃ (18 ℉) higher than the maximum temperature of the enclosure measured during the normal operations and keep for 7 hours. After removal from the oven, the sample should be subjected to a dielectric voltage withstand test. There should be no cracking of the enclosure or dielectric breakdown.

Seismic environment

There is equipment that cannot be practically evaluated by testing alone because of the size of the equipment. For those situations, it may be necessary to do a combination of analysis with testing of parts of the system. This approach is outlined in IEEE 344.

New Added ANNEX

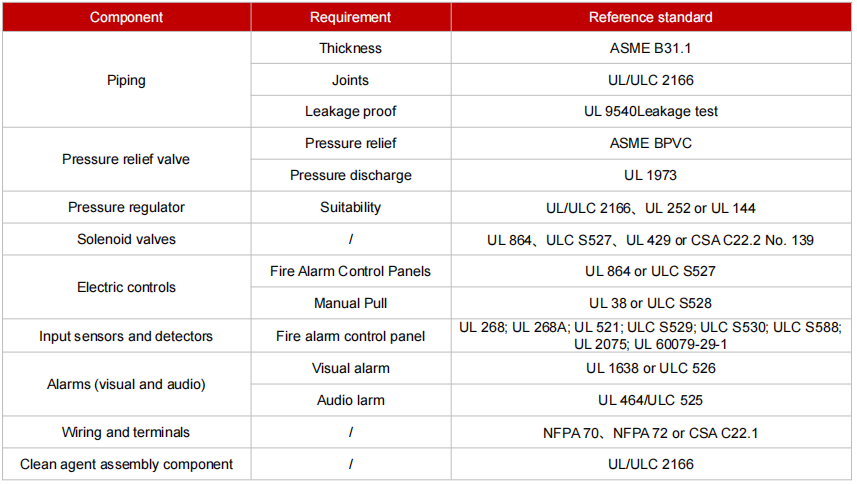

Add annex G — CLEAN AGENT DIRECT INJECTION BATTERY RACK COOLANT SYSTEM UNITS

CLEAN AGENT – Electrically nonconducting, volatile, or gaseous fire extinguishant that does not leave a residue upon evaporation.

DIRECT INJECTION BATTERY RACK COOLANT SYSTEM UNIT – Identified parts that are assembled into a system for the discharge of a clean agent through fixed piping and nozzles for the purpose of cooling battery modules to limit thermal runaway propagation within a stationary battery rack/battery energy storage system.

This can also be considered as a fire extinguishment system for ESS

Construction:

Performance

- Clean agent assembly tests (UL/ULC 2166)

- Start to discharge test

- Direct injection coolant system tests — Large scale fire test (Unit level or installation level test in UL 9540A)

Post time: Sep-12-2023