Overview of the Standard

General Specification for the Space-using Li-ion Storage Battery was put forward by China Aerospace Science and Technology Corporation and issued by Shanghai Institute of Space Power-Sources. Its draft has been on public service platform to canvass opinion. The standard gives regulations on the terms, definition, technical requirement, test method, quality assurance, package, transportation and storage of Li-ion storage battery. The standard applies for the space-using li-ion storage battery (hereinafter referred to as “Storage Battery”).

Requirement of the Standard

Appearance and mark: The appearance should be intact; the surface should be clean; the parts and components should be complete. There should be no mechanical defects, no extras and other defects. The product identification shall include the polarity and traceable product number, where the positive pole is represented by “+” and the negative pole is represented by “-“.

Dimensions and weight: the dimensions and weight should be consistent with the technical specifications of the storage battery.

Airtightness: the leakage rate of the storage battery is not more than 1.0X10-7Pa.m3.s-1; after the battery is subjected to 80,000 fatigue life cycles, the welding seam of the shell should not be damaged or leaked, and the burst pressure should not be lower than 2.5MPa.

For the requirements of tightness, two tests are designed: leakage rate and shell burst pressure; the analysis should be on test requirements and test methods: these requirements mainly consider the leakage rate of the battery shell under low pressure conditions and its ability to withstand gas pressure.

Electrical performance: ambient temperature (0.2ItA, 0.5ItA), high temperature, low temperature capacity, charge and discharge efficiency, internal resistance (AC, DC), charged retention capacity, pulse test.

Environmental adaptability: vibration (sine, random), shock, thermal vacuum, steady- state acceleration Compared to other standards, thermal vacuum and steady-state acceleration test chambers have a special requirement; in addition, the acceleration of the impact test reaches 1600g, which is 10 times the acceleration of the commonly used standard.

Safety Performance: short circuit, overcharge, overdischarge, over-temperature test.

The external resistance of the short-circuit test should be no more than 3mΩ, and the duration is 1min; the overcharge test is carried out for 10 charge and discharge cycles between 2.7 and 4.5V specified current; the overdischarge is carried out between -0.8 and 4.1V (or set value) for 10 charging and discharging cycles; the over-temperature test is to charge under specified conditions of 60℃±2℃.

Life performance: Low Earth Orbit (LEO) cycle life performance, Geosynchronous Orbit (GEO) cycle life performance.

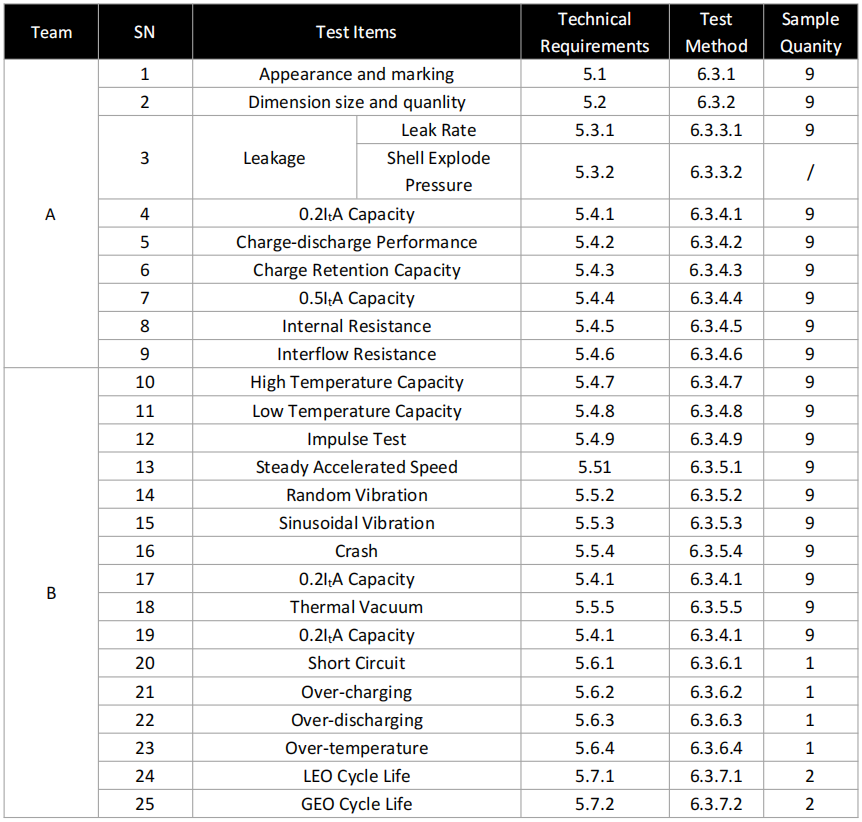

Test items and sample quantity

Conclusion & Analysis

Lithium battery is widely applied in aviation, and it has corresponding standards and regulations abroad, e.g. DO-311 series standard issued by American Airline Wireless Technical Committee. But it is the first time for China to set national standard in this field. It may states that the production and manufacture of Lithium batteries for aviation will be open for general enterprises. Along with the further mature of manned spaceflight, aerospace endeavor will develop in commercialization direction. The purchase of aviation spare parts will be marketization. And lithium battery, as one of spare parts, will be one of the purchased products.

Regarding intense competition all walks of life about lithium battery today, it is key to get competitive edge in marking on new direction and research in new field early. Enterprise starts to consider the development of aerospace battery may lay a solid footstone for their future development.

Post time: Nov-18-2021