Overview:

Crush is a very typical test to verify the safety of cells, simulating the crush collision of cells or end products in daily use. There are generally two types of crush tests: flat crush and partial crush. Compared to the flat crush, the partial indentation caused by a spherical or cylindrical indenter is more likely to cause the cell ineffective. The sharper the indenter, the more concentrated the stress on the core structure of the lithium battery, the more serious the rupture of the inner core, which will cause deformation and displacement of the core, and even lead to serious consequences such as electrolyte leakage or even fire. So how does crush lead to the deactivation of the cell? Here introduce you to the internal structure evolution of the core in the local extrusion test.

Crush process:

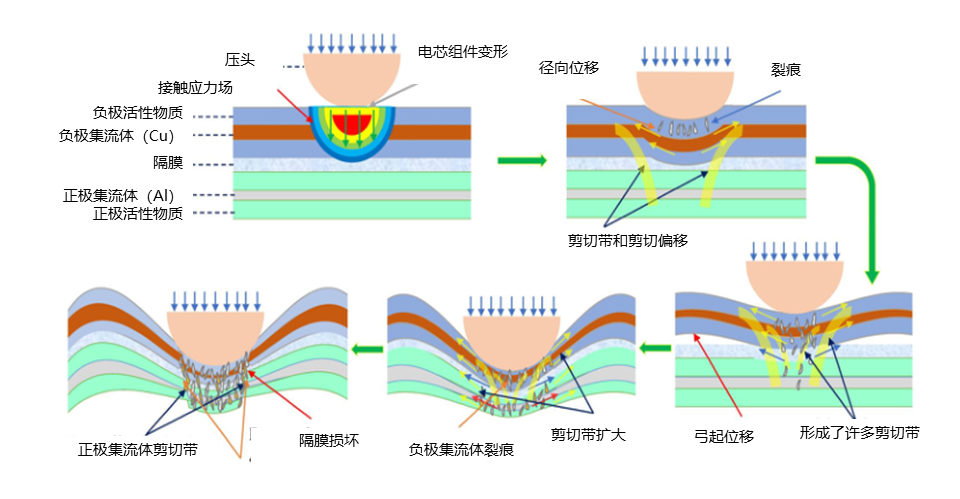

- The squeezing force is applied to the cell enclosure first, and the enclosure deforms. The force is then transferred to the inside of the battery, and the cell assembly also starts to deform.

- With further compression of the crush head, the deformation is expanding and localization is formed. At the same time, the layer spacing between each electrode layer is gradually shortened. Under continuous compression, the current collector is bent and deformed, and shear bands are formed. When the deformation of the electrode material reaches the limit, the electrode material will produce cracks.

- With the increase of deformation, the crack gradually extends to the current collector, which will be torn and produce ductile fracture. In addition, the radial crack is elongated due to the increase of stress and radial displacement.

- At this point, the extrusion force continues to compress the cell, causing more electrode layers to suffer deformation, which leads to expansion of the shear zone, change in inclination angle (45°), and further expansion of the shear zone range.

- Finally, as the diaphragm continues to be stretched and twisted, the cracks extend to the diaphragm. When it reaches the deactivation point, the diaphragm is torn and adjacent electrodes come into contact, forming an internal short-circuit. At this point, a large short-circuit current is generated at the short-circuit point, leading to intense heating and rapid rise of temperature, which will trigger the side reactions within the cell and eventually thermal abuse may occur.

Summary:

Crush test is a kind of mechanical abuse. Mechanical abuse is an unavoidable safety hazard in the daily use of lithium-ion batteries, which can lead to the rupture of the diaphragm and trigger an internal short circuit. However, due to the shape of the crush head, the size of the crush pressure and the strength of the cell itself varies, the results of the crush test often vary greatly. Optimization on the cell material or structure is needed to avoid the deactivation of the cell brought by crush test as much as possible. For example, the use of a safer, more ductile diaphragm or the improvement on heat dissipation performance of cell can greatly prevent thermal abuse when internal short-circuit occurs.

Post time: Oct-11-2022