Background

The energy crisis has made lithium-ion battery energy storage systems (ESS) more widely used in the past few years, but there have also been a number of dangerous accidents resulting in damage to facilities and the environment, economic loss, and even loss of life. Investigations have found that even though ESS have met standards related to battery systems, such as UL 9540 and UL 9540A, thermal abuse and fires have occurred. Therefore, learning lessons from past cases and analyzing the risks and their countermeasures will benefit the development of ESS technology.

Cases review

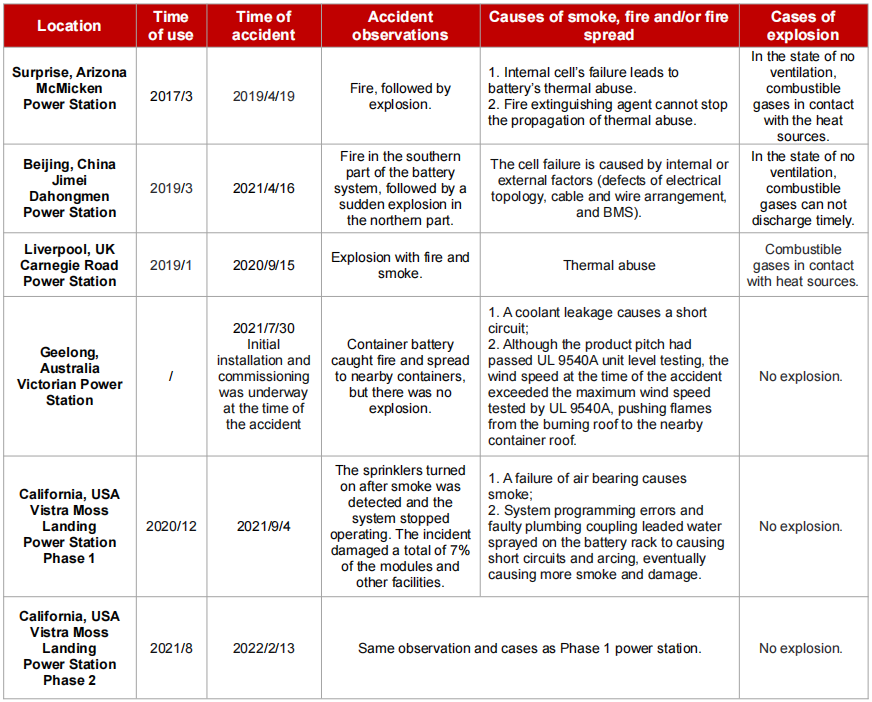

The following summarizes accident cases of large-scale ESS around the world from 2019 to date, which have been publicly reported.

The causes of the above accidents can be summarized as the following two:

1) A failure of internal cell triggers thermal abuse of the battery and module, and finally causes the entire ESS to catch fire or explode.

The failure caused by thermal abuse of cell is basically observed that a fire followed by an explosion. For example, accidents of the McMicken power station in Arizona, USA in 2019 and the Fengtai power station in Beijing, China in 2021 both exploded after a fire. Such phenomenon is caused by the failure of a single cell, which triggers an internal chemical reaction, releasing heat (exothermic reaction), and the temperature continues to rise and spread to nearby cells and modules, causing a fire or even an explosion. The failure mode of a cell is generally caused by overcharge or control system failure, thermal exposure, external short circuit and internal short circuit (which can be caused by various conditions such as indentation or dent, material impurities, penetration by external objects, etc.).

After the thermal abuse of the cell, flammable gas will be produced. From above you can notice that the first three cases of explosion have the same cause, that is flammable gas can not discharge timely. At this point, the battery, the module and the container ventilation system are particularly important. Generally gases are discharged from the battery through the exhaust valve, and the pressure regulation of the exhaust valve can reduce the accumulation of combustible gases. In the module stage, generally an external fan or a shell’s cooling design will be used to avoid the accumulation of combustible gases. Finally, in the container stage, ventilation facilities and monitoring systems are also required to evacuate combustible gases.

2) ESS failure caused by external auxiliary system failure

An overall ESS failure caused by an auxiliary system failure typically occurs outside of the battery system and may result in burning or smoke from external components. And when the system monitored and responded to it in a timely manner, it will not lead to cell’s failure or thermal abuse. In the accidents of Vistra Moss Landing Power station Phase 1 2021 and Phase 2 2022, smoke and fire were generated because the fault monitoring and electrical fail-safe devices were turned off at that time during the commissioning phase and could not respond in a timely manner. This kind of flame burning usually starts from the outside of the battery system before it finally spreads to the inside of the cell, so there is no violent exothermic reaction and combustible gas accumulation, and so usually no explosion. What’s more, if the sprinkler system can be turned on in time, it will not cause extensive damage to the facility.

The “Victorian Power Station” fire accident in Geelong, Australia in 2021 was caused by a short circuit in the battery caused by a coolant leakage, which reminds us to pay attention to the physical isolation of the battery system. It is recommended to keep a certain space between external facilities and the battery system to avoid mutual interference. The battery system should also be equipped with insulation function to avoid external short circuit.

Countermeasures

From the above analysis, it is clear that the causes of ESS accidents are the thermal abuse of the cell and the failure of the auxiliary system. If the failure cannot be prevented, then reducing the further deterioration after the blocking failure can also reduce the loss. The countermeasures can be considered from the following aspects:

Blocking the thermal spread after thermal abuse of the cell

Insulation barrier can be added to block the spread of thermal abuse of the cell, which can be installed between the cells, between the modules or between the racks. In the appendix of NFPA 855 (Standard for the Installation of Stationary Energy Storage Systems), you can also find the related requirements. Specific measures to isolate the barrier include inserting cold water plates, aerogel and likes between the cells.

A fire suppression device to the battery system can be added so that it can react quickly to activate the fire suppression device when thermal abuse occurs in an single cell. The chemistry behind lithium-ion fire hazards leads to a different fire suppression design for energy storage systems than conventional firefighting solutions, which is not only to extinguish the fire, but also to reduce the temperature of the battery. Otherwise, the exothermic chemical reactions of the cells will continue to occur and trigger a re-ignition.

Extra care is also needed when selecting fire extinguishing materials. If the water is sprayed directly on the burning battery casing may produce a flammable gas mixture. And if the battery casing or frame is made of steel, water will not prevent thermal abuse. Some cases show that water or other types of liquids in contact with the battery terminals may also exacerbate the fire. For example, in the fire accident of Vistra Moss Landing power station in September 2021, reports indicated that the station’s cooling hoses and pipe joints failed, causing water to spray on the battery racks and ultimately causing the batteries to short circuit and arc.

1.Timely emission of combustible gases

All of the above case reports point to concentrations of combustible gases as the primary cause of explosions. Therefore, site design and layout, gas monitoring and ventilation systems are important for reducing this risk. In NFPA 855 standard there is mentioned that a continuous gas detection system is required. When a certain level of combustible gas (i.e. 25% of LFL) is detected, the system will start exhaust ventilation. In addition, UL 9540A test standard also mentions the requirement to collect exhaust and detect the lower limit of gas LFL.

In addition to venting, the use of explosion relief panels is also recommended. It is mentioned in NFPA 855 that ESSs are to be installed and maintained in accordance with NFPA 68 (Standard on Explosion Protection by Deflagration Venting) and NFPA 69 (Standards on Explosion Protection Systems). However, when the system complies with the Fire and Explosion Test (UL 9540A or equivalent), it can be exempt from this requirement. However, as the conditions of testing are not fully representative of the true situation, an enhancement of ventilation and explosion protection is recommended.

2.Failure prevention of auxiliary systems

Inadequate software/firmware programming and commissioning/pre-start procedures also contributed to the Victorian Power Station and Vistra Moss Landing Power Station fire incidents. In the Victorian Power Station fire, a thermal abuse initiated by one of the modules was not identified or blocked, and the fire following was not interrupted either. The reason why this situation happened is that commissioning was not required at the time, and the system was manually shut down, including telemetry system, fault monitoring and electrical fail-safe device. In addition, the Supervisory Control and Data Acquisition (SCADA) system was also not yet operational, as it took 24 hours to establish equipment connectivity.

Therefore, it is recommended that any idle modules should have devices like active telemetry, fault monitoring and electrical safety devices, rather than being manually shut down via a lock-out switch. All electrical safety protection devices should be kept in active mode. In addition, additional alarm systems should be added to identify and respond to various emergency events.

A software programming error was also found in the Vistra Moss Landing Power station Phases 1 and 2, as the start-up threshold was not exceeded, the battery heat sink was activated. At the same time, the water pipe connector failure with the leakage of upper layer of the battery make the water available to the battery module and then cause short circuit. These two examples show how important it is for software/firmware programming to be checked and debugged prior to the start-up procedure.

Summary

Through the analysis of several fire accidents in energy storage station, high priority should be given to ventilation and explosion control, proper installation and commissioning procedures, including software programming checks, which can prevent battery accidents. In addition, a comprehensive emergency response plan should be developed to deal with the generation of toxic gases and substances.

Post time: Jun-07-2023