Li-ion smart watches recalled

Li-ion smart watches recalled,

smart watche,

▍What is TISI Certification?

TISI is short for Thai Industrial Standards Institute, affiliating to Thailand Industry Department. TISI is responsible for formulating the domestic standards as well as participating in international standards formulation and supervising the products and qualified assessment procedure to ensure the standard compliance and recognition. TISI is a governmental authorized regulatory organization for compulsory certification in Thailand. It is also responsible for formation and management of standards, lab approval, personnel training and product registration. It is noted that there is no non-governmental compulsory certification body in Thailand.

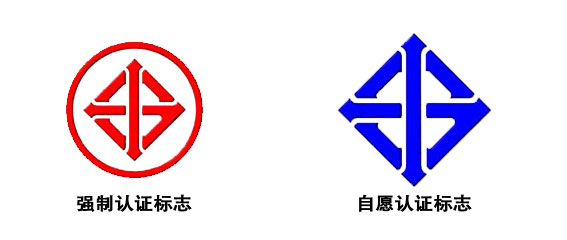

There is voluntary and compulsory certification in Thailand. TISI logos (see Figures 1 and 2) are allowed to use when products meet the standards. For products that have not yet been standardized, TISI also implements product registration as a temporary means of certification.

▍Compulsory Certification Scope

The compulsory certification covers 107 categories, 10 fields, including: electrical equipment, accessories, medical equipment, construction materials, consumer goods, vehicles, PVC pipes, LPG gas containers and agricultural products. Products beyond this scope are fall within the voluntary certification scope. Battery is compulsory certification product in TISI certification.

Applied standard: TIS 2217-2548 (2005)

Applied batteries:Secondary cells and batteries(containing alkaline or other non-acid electrolytes – safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications)

License issuance authority: Thai Industrial Standards Institute

▍Why MCM?

● MCM cooperates with factory audit organizations, laboratory and TISI directly, capable to provide best certification solution for clients.

● MCM possesses 10 years abundant experience in battery industry, capable to provide professional technical support.

● MCM provides one-stop bundle service to help clients enter into multiple markets (not only Thailand included) successfully with simple procedure.

The energy storage equipment caught fine in Salt Lake substation in Arizona, US on April 18th, bringing a continuous burning for 5 days and kept smoking. The local fire department kept monitoring the condition of equipment, and on 21st addressed all the employees shall evacuate before 6 p.m.

The energy storage caught with accident located at around Arizona Road Chandler 10 and 56th street in the southeast of No.202 beltway. There are 3200 pieces of li-ion batteries, with total capacity of 10MW/40MWh in that base, which is the first state owned energy storage project first disclosed in 2018. The solution of the project is provided by Fluence, and Mortenson is the EPC.

According to the local officials, they have noticed all the enterprises 0.25 feet around to evacuate at 6 p.m. on 21st.Conclusion: As li-ion batteries are more widely used, from Bluetooth buds to container energy storage, the safety is under great emphasis. The risk shall be lowered at the stages of design and manufacture; meanwhile the testing procedure shall be more effective, so that we can avoid accident occurring in transporting, using and recycling.