Fire Process of Lithium Battery

Fire Process of Lithium Battery,

lithium battery,

▍What is TISI Certification?

TISI is short for Thai Industrial Standards Institute, affiliating to Thailand Industry Department. TISI is responsible for formulating the domestic standards as well as participating in international standards formulation and supervising the products and qualified assessment procedure to ensure the standard compliance and recognition. TISI is a governmental authorized regulatory organization for compulsory certification in Thailand. It is also responsible for formation and management of standards, lab approval, personnel training and product registration. It is noted that there is no non-governmental compulsory certification body in Thailand.

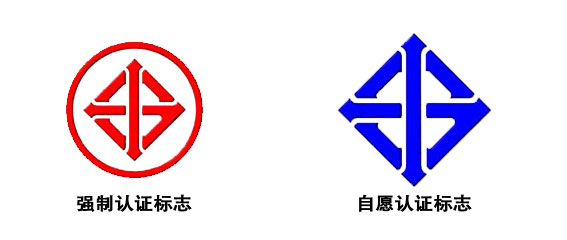

There is voluntary and compulsory certification in Thailand. TISI logos (see Figures 1 and 2) are allowed to use when products meet the standards. For products that have not yet been standardized, TISI also implements product registration as a temporary means of certification.

▍Compulsory Certification Scope

The compulsory certification covers 107 categories, 10 fields, including: electrical equipment, accessories, medical equipment, construction materials, consumer goods, vehicles, PVC pipes, LPG gas containers and agricultural products. Products beyond this scope are fall within the voluntary certification scope. Battery is compulsory certification product in TISI certification.

Applied standard: TIS 2217-2548 (2005)

Applied batteries:Secondary cells and batteries(containing alkaline or other non-acid electrolytes – safety requirements for portable sealed secondary cells, and for batteries made from them, for use in portable applications)

License issuance authority: Thai Industrial Standards Institute

▍Why MCM?

● MCM cooperates with factory audit organizations, laboratory and TISI directly, capable to provide best certification solution for clients.

● MCM possesses 10 years abundant experience in battery industry, capable to provide professional technical support.

● MCM provides one-stop bundle service to help clients enter into multiple markets (not only Thailand included) successfully with simple procedure.

Regardless of what situation causing the battery fire or explodes, the root cause is the short circuit inside or outside the cell, which resulting in thermal runaway of the cell. After the thermal runaway of a single cell, it will eventually lead to the entire pack catching fire if thermal propagation cannot be avoided due to structure design of module or pack. Causes of internal or external short circuit of the cell are (but not limited to): overheating, overcharge, over discharge, mechanical force (crush, shock), circuit aging, metal particles into the cell in production process, etc.To reduce the safety risks of the battery pack, firstly, the cell should have a high safety quality, and secondly, PCB should have a good durability. The high safety quality of the cell mainly refers to the good consistency of the cell, which means no foreign matter can enter the roll core in the production process of the cell; the good durability of the PCB mainly refers to the long cycle life and high reliability of the protection function.The cause of the fire in the non-use process of electric vehicles is concerned with the safety quality of the cell. Actually the root cause is still in the using process, when the cell is not damaged yet and causes fire; but after a period of self-reaction, the cell completely out of control. The cause of the fire in the charging process may be concerned with the failure of protection function or the imbalance of cell voltage in battery pack, as well as charging heat. The cause of the fire in the driving process may be concerned with the voltage imbalance of cell and the untimely heat dissipation.