A Review and Reflection of Several Fire Incidents of Large-scale Lithium-ion Energy Storage Station

A Review and Reflection of Several Fire Incidents of Large-scale Lithium-ion Energy Storage Station,

Lithium-ion,

▍Document requirement

1. UN38.3 test report

2. 1.2m drop test report (if applicable)

3. Accreditation report of transportation

4. MSDS(if applicable)

▍Testing Standard

QCVN101:2016/BTTTT(refer to IEC 62133:2012)

▍Test item

1.Altitude simulation 2. Thermal test 3. Vibration

4. Shock 5. External short circuit 6. Impact/Crush

7. Overcharge 8. Forced discharge 9. 1.2mdrop test report

Remark: T1-T5 is tested by the same samples in order.

▍ Label Requirements

|

Label name |

Calss-9 Miscellaneous Dangerous Goods |

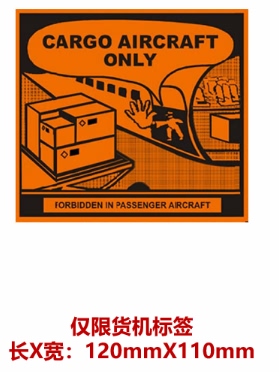

Cargo Aircraft Only |

Lithium Battery Operation Label |

|

Label picture |

|

|

▍Why MCM?

● The initiator of UN38.3 in the transportation field in China;

● Have the resources and professional teams being able to accurately interpret UN38.3 key nodes related to Chinese and foreign airlines, freight forwarders, airports, customs, regulatory authorities and so on in China;

● Have resources and capabilities that can help lithium-ion battery clients to “test once, pass smoothly all airports and airlines in China “;

● Has the first-class UN38.3 technical interpretation capabilities, and housekeeper type service structure.

The energy crisis has made lithium-ion battery energy storage systems (ESS) more widely used in the past few years, but there have also been a number of dangerous accidents resulting in damage to facilities and the environment, economic loss, and even loss of life. Investigations have found that even though ESS have met standards related to battery systems, such as UL 9540 and UL 9540A, thermal abuse and fires have occurred. Therefore, learning lessons from past cases and analyzing the risks and their countermeasures will benefit the development of ESS technology.The following summarizes accident cases of large-scale ESS around the world from 2019 to date, which have been publicly reported.The causes of the above accidents can be summarized as the following two:

1) A failure of internal cell triggers thermal abuse of the battery and module, and finally causes the entire ESS to catch fire or explode.

The failure caused by thermal abuse of cell is basically observed that a fire followed by an explosion. For example, accidents of the McMicken power station in Arizona, USA in 2019 and the Fengtai power station in Beijing, China in 2021 both exploded after a fire. Such phenomenon is caused by the failure of a single cell, which triggers an internal chemical reaction, releasing heat (exothermic reaction), and the temperature continues to rise and spread to nearby cells and modules, causing a fire or even an explosion. The failure mode of a cell is generally caused by overcharge or control system failure, thermal exposure, external short circuit and internal short circuit (which can be caused by various conditions such as indentation or dent, material impurities, penetration by external objects, etc.).

After the thermal abuse of the cell, flammable gas will be produced. From above you can notice that the first three cases of explosion have the same cause, that is flammable gas can not discharge timely. At this point, the battery, the module and the container ventilation system are particularly important. Generally gases are discharged from the battery through the exhaust valve, and the pressure regulation of the exhaust valve can reduce the accumulation of combustible gases. In the module stage, generally an external fan or a shell’s cooling design will be used to avoid the accumulation of combustible gases. Finally, in the container stage, ventilation facilities and monitoring systems are also required to evacuate combustible gases.